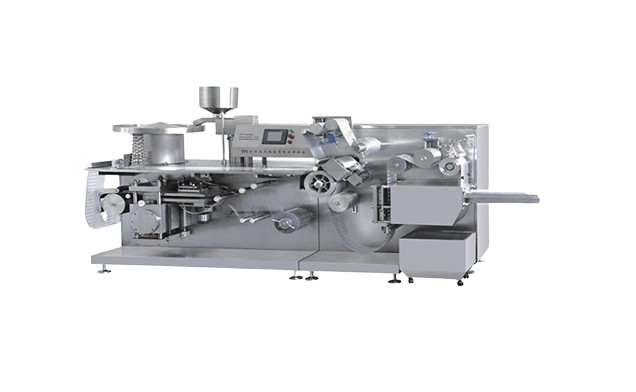

- Convenient mould changing

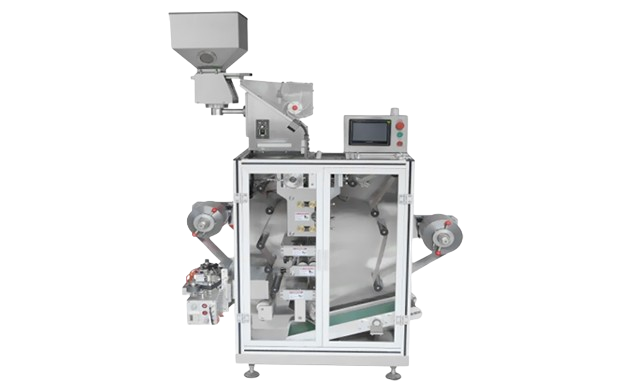

- Closed structure design

- The equipment design station and power area are separated before and after

- Standard servo motor traction

- Horizontal brush dust suction

- Can reserve connection interface

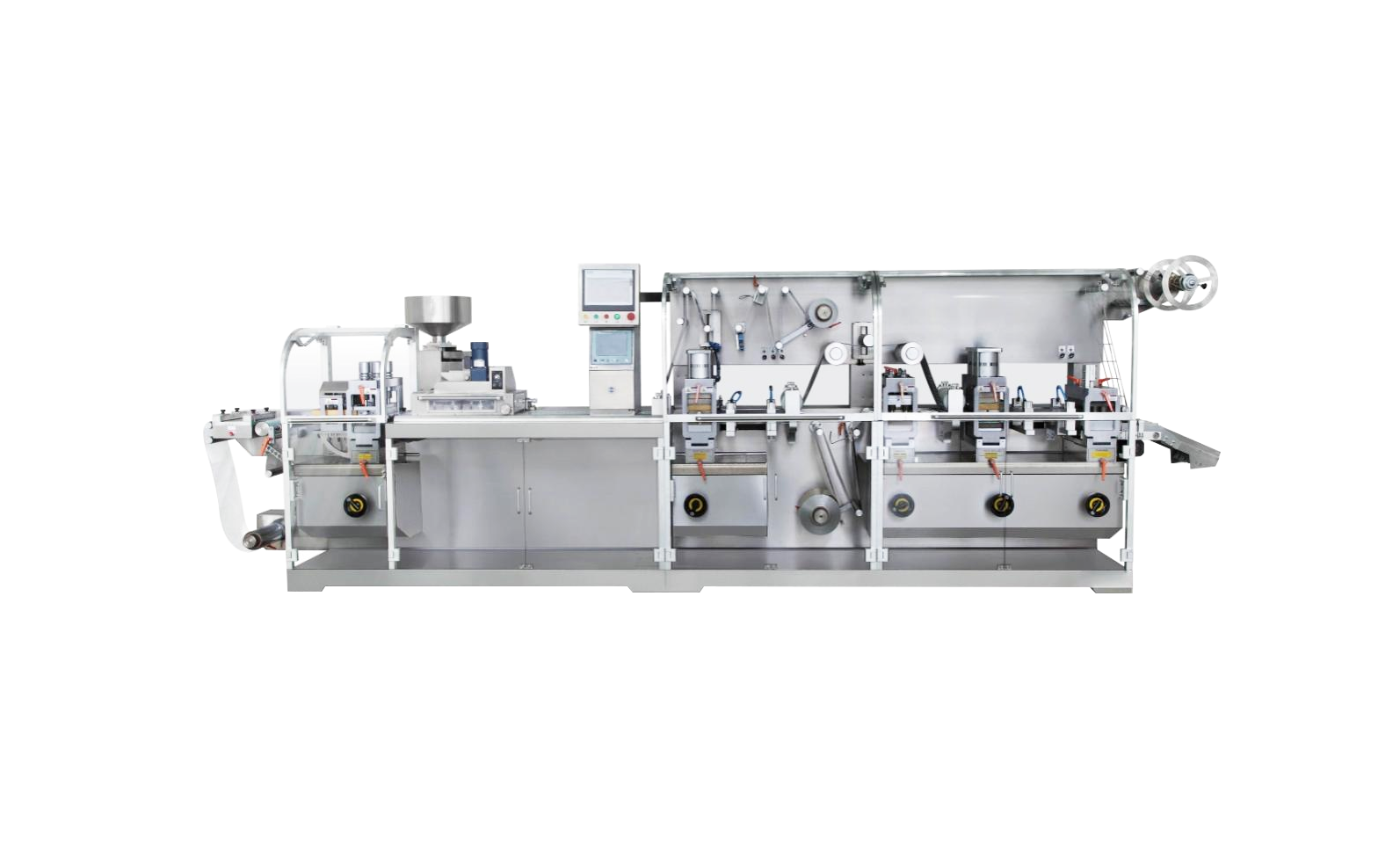

SED-TP-B

PVC ALU Aluminum Foil Blister Pack Machine

SED-TP-B aluminum foil blister packaging machine is suitable for blister packing with Aluminum-Plastic, Aluminum-Aluminum, and Aluminum-Plastic-Aluminum. It is suitable for product packaging in pharmaceuticals, food, medical devices, health products, and other industries.

features

SPECS

Features & Benefits

TECHNICAL DATA & Benefits

| Model | SED-270TP-B |

| Punch Frequency (cut/min) | 10-40 |

| Capacity (plates/min) | 140 |

| Max. Forming Area (mm²) | 260*110 |

| Section Reference Specifications | Standard:80×57mm Reference specifications:80×57 95×65 103×43 120×43 |

| Packaging Material | Non-toxic PVC hard film: 0.15—0.5mm×270mm Coated PTP aluminium foil: 0.02—0.035mm×270mm Tropical aluminium: 0.09—0.15mm×270mm Cold formed aluminium foil: 0.13-0.015mm×270mm The diameter of the reel: 70—76mm |

| Heating Power Consumption (kW) | forming heating:1.5 sealing heating:1.5 |

| Power Supply | 380V/50Hz 10kW |

| Main Motor | 100L1-4(2.2kW) |

| Air Pump Capacity | >0.2m³/min 0.6-0.8MPa |

| Mold Cooling | Tap water or circulating water, consumption 60L/hr |

| Table Length (mm) | 1400 |

| Dimensions (L*W*H mm) | 5360*850*1750 |

| Weight (kg) | 4000 |

Application

Easy to Clean and Maintain

Professional After-Service Team

Stable Operation and Reasonable Structure