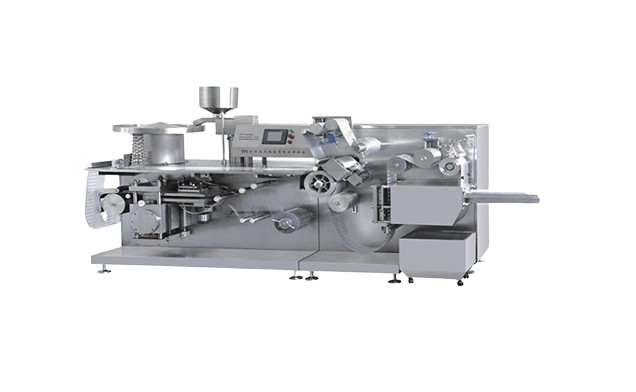

- Mold can easily be changed

- The material is fed automatically (the mould and feeding equipment can be customized)

- The heating moulds will automatically separate when the machine stops, to protect the material between them and extend the machine’s life

- Manipulator grip and tow wrapper, straight to and from running, synchronize accurately and stably.

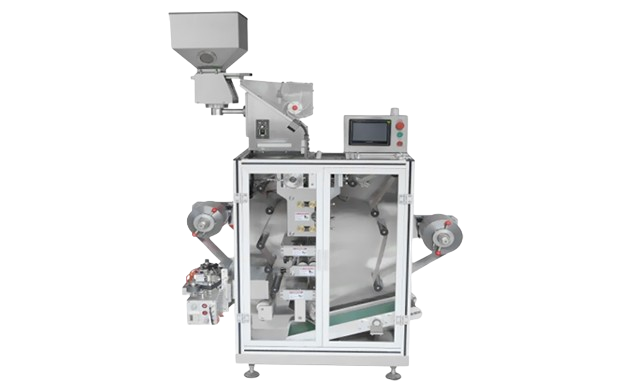

- Small in footprint, saving room and cost

- Multi-function: Forming, sealing, code date or perforating, and die cutting

- It covers thermo and cold forming, plugs assist deep forming for complicated shapes, vacuum/blow/plug forming, etc.

- Forming materials: PVC, PTP, PET, Cold form aluminum foil, etc.

- An automatic format positioning system achieves straightforward format changeover

- Window frame type no-waste-trimming cutter saves packaging materials

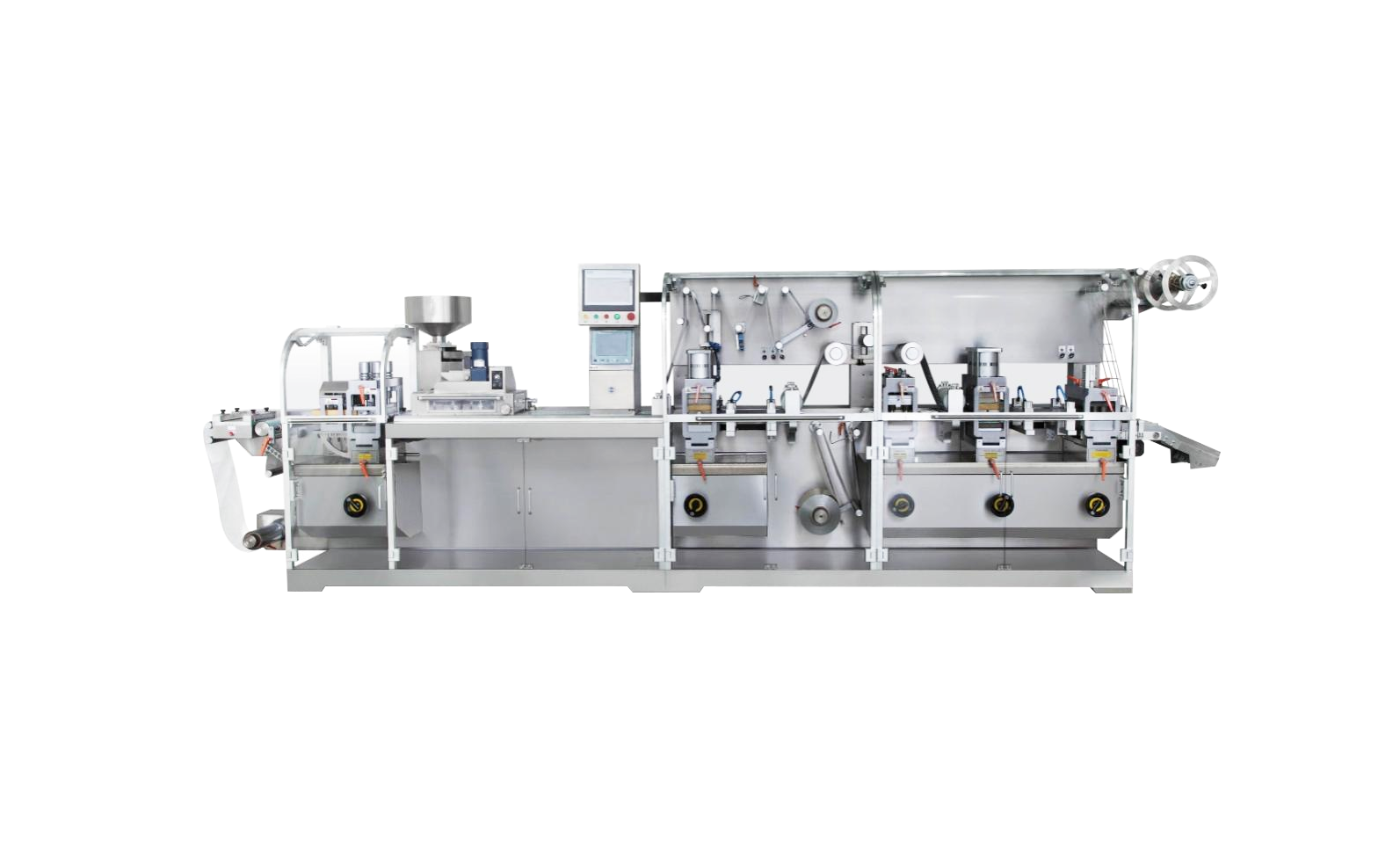

SED-P-A

Thermoforming Blister Packaging Machine

SED-P Series thermoforming Blister Packaging Machine is commonly used in the food and medical packaging industries, the shapes of blister and mold vary with the shape of the packaged goods.

features

SPECS

Features & Benefits

TECHNICAL DATA & Benefits

| Model | SED-88P-A | SED-140P-A | SED-250P-A | SED-260P-A | SED-350P-A |

| Punch Frequency (cut/min) | 10-33 | 15-30 | 15-45 | 15-50 | 15-50 |

| Capacity (plates/min) | 33 | 30 | 45 | 50 | 50 |

| Max. Forming Area (mm²) | 90*70 | 140*110 | 250*120 | 250*110 | 350*130 |

| Max. Forming Depth (mm) | 15-25 | 15-20 | 15-30 | 12-15 | 12-50 |

| Standard Stroke Range (mm) | 30-80 | 30-120 | 30-130 | 30-120 | 30-140 |

| Air Pressure (MPa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.6-0.8 | 0.6-0.8 |

| Compressed Air Required (m³/min) | ≥0.3 | ≥0.4 | ≥0.45 | ≥0.25 | ≥0.25 |

| Power Supply | 220V 50Hz 2.4kW | 380V/220V 50Hz 5.5kW | 380V/220V 50Hz 8kW | 380V 50Hz 8kW | 380V 50Hz 12kW |

| PVC Hard Sheet (mm) | (0.15-0.5)*110 | (0.15-0.5)*160 | (0.15-0.5)*270 | (0.15-0.4)*270 | (0.15-0.4)*350 |

| PTP Aluminum Film (mm) | (0.02-0.035)*110 | (0.02-0.035)*160 | (0.02-0.035)*270 | (0.02-0.15)*270 | (0.02-0.15)*350 |

| Dialysis Paper | (50-100)g/m²*110 | (50-100)g/m²*160 | (50-100)g/m²*270 | (50-100)g/m²* 270 | (50-100)g/m²*350 |

| Overall Dimension (L*W*H mm) | 1840*590*1100 | 2400*650*1450 | 2900*750*1600 | 3550*900*1900 | 4000*1000*2000 |

| Weight (kg) | 465 | 800 | 1200 | 2000 | 2300 |

Application

Easy to Clean and Maintain

Professional After-Service Team

Stable Operation and Reasonable Structure